Rice Processing Plant

Meticulously tested on various quality parameters under the guidance of our experienced professionals, these large scale complete rice processing lines are recognized for its reliable performance, less maintenance, longer service life, and enhanced durability.

-

Capacity

10-500 ton/d final rice

-

Service

Customization, installation, guidance and training

-

Cooperation

Factory Directly

-

Power

500kw

-

Include Machine

rice destoner, rice huller, rice separator, rice mill, rice grader, and rice bucket elevator, etc

Product Introduce

The complete rice processing plant is designed to produce high quality refined rice. From paddy cleaning to rice packing, the operation is completely automatical controlled. Meticulously tested on various quality parameters under the guidance of our experienced professionals, these large scale complete rice processing lines are recognized for its reliable performance, less maintenance, longer service life, and enhanced durability.

Complete rice milling plant is the process that helps to detach hulls and bran's from paddy grains to produce polished rice. The objective of a rice milling system is to remove the husk and the bran layers from paddy rice to produce whole white rice kernels that are sufficiently milled free of impurities and contain a minimum number of broken kernels.

Rice Milling Plant consists of rice destoner, rice huller, rice separator, rice mill, rice grader, and rice bucket elevator, etc. It includes the whole process from paddy cleaning, hulling, paddy separation, rice milling to rice sorting.

- Single motor drive, electric console

- Flexible and customized technology. It can process rice with different precision.

- Static spraying plastics technology, bright and artistic appearance, colorfast.

- Nice and durable glass elephant trunk.

- Efficient dust collecting device, environmental protection.

| Brief equipment for customers' reference, contact us for more information, we will give you appropriate scheme according to your requirements. | ||||

| Main Equipment | Product name | Mode | Quantity | Power |

| Cleaner and destoner | ZQSX60*5 | 1 | 0.5 | |

| Magnetic separator | QCX-30 | 1 | ||

| Rice huller | MLGT20 | 1 | 4 | |

| Paddy separator | MGCZ100*5 | 1 | 1.1 | |

| Rice mill | MNMS15 | 2 | 30 | |

| Rice grader | MMQP63*3 | 1 | 1.1 | |

| Rice polisher | MLNS14 | 1 | 15 | |

| Color sorter | CR-CCD78 | 1 | 1.5 | |

| Packing machine | DS-50 | 1 | 1.5 | |

Projects Cases:

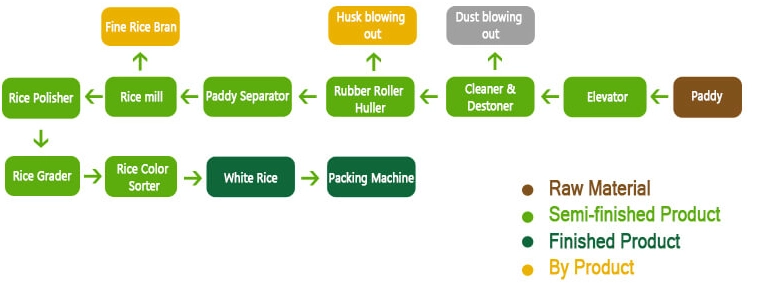

Rice milling machine processing flow

Process Flow of Rice Processing Plant

- 1. Cleaning: In this stage we remove the dust from the paddy, if the paddy has dust when it is soaking it will pollute the water and influence the nutrition of rice.

- 2. Husking: After soaking and steaming it will be very easy to husk the paddy and save energy.

- 3. Milling: The pearling of pre-boiled rice cost much more time than normal paddy. The reason is that after soaking the rice is easy to become smectic. To avoid this problem we use blowing rice miller, and increase the rotating speed of rice miller,the rice bran transmission adopt neaumatic type to reduce the friction.

- 4. Polishing and Grading: Grading machine is used to separate different quality rice and separate broken rice from the good ones. Good rice come through the polishing machine, it will make the milling rice become more beautiful color and more smooth, thus to increase the quality of rice.

- 5. Color sorting: The rice we get from above step still has some bad rice, broken rice or some other grains or stone. So here we use color sorting machine to select the bad rice and other grains. Color sorting machine is an important machine to ensure we can get high quality rice.

- 6. Packing: The finish rice now is ready dear all! Let's use our automatic weighing and packing machine to make them into 5kg 10kg or 50kg bags. This machine is electric type, you can set it like a small computer, then it will start working according to your request.

Interested in this machine.

Application

Comparison before and after rice processing

-----processed rice is round and bright, and the food tastes better-----

Before rice processing