Rice Milling Plant

This rice mill machine is choose excellent vibratory sieve,destoner- rubber roller husker, paddy separator, rice whitener, white rice plan sifter and high efficient fo the bucket elevator and electrical console of complete sets of rice milling machine, whole process of rice cleaning, hulling, husking, roughing and milling is carried out automatically and continuously.

-

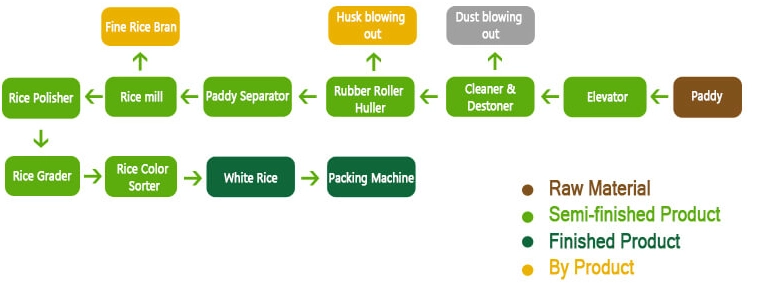

Flow Chart

Paddy Cleaner → Destoner → Paddy husker → Paddy Separator → Rice Whitener → water polisher → Rice Grader → Color Sorter → Packing

Product Introduce

Complete rice milling plant is the process that helps to detach hulls and bran's from paddy grains to produce polished rice. The objective of a rice milling system is to remove the husk and the bran layers from paddy rice to produce whole white rice kernels that are sufficiently milled free of impurities and contain a minimum number of broken kernels.

Rice milling machine processing flow

| Pre Cleaning | Removing all impurities and unfilled grains from raw paddy |

| De-stoning | Separating small stones from paddy |

| Parboiling (Optional) | Improving the nutritional quality and milling recovery percent during husking and polishing / whitening operation |

| Husking | Removing husk from paddy |

| Husk Aspiration | Separating the husk from brown rice/ unhusked paddy |

| Paddy Separation | Paddy Separation |

| Whitening | Removing all or part of the bran layer and germ from brown rice |

| Polishing | Improving the appearance of milled rice by removing the remaining bran particles and by polishing the exterior of milled kernel |

| Color Sorting (Optional) | Removing foreign materials such as colored, broken, immature and insected grains from milled rice |

| Length Grading | Separating small and large brokens from head rice |

| Blending | Mixing head rice with predetermined amount of brokens, as required by the customer |

| Weighing and Bagging | Preparing the milled rice for transport to the customer |

Advantage of rice milling plant

- More than 95% separate rate of white rice and brown husk

- High working efficiency to help save labor and time.

- Low power consumption and low noise

- With an elevator machine can promise automatic work.

- machine different motor drive for more convenient use.

Features of rice processing line

- The rice mill machine adopts the advantages of other types, it has a comprehensive layout, rational design, compact structure and little noise .

- It is easy to operate and less power consumption, high productivity.

- The model rice mill can produce white rice with high purity .

- The finished rice contains less chaff and low broken rate.

Process Flow of Rice Processing Plant

- 1. Cleaning: In this stage we remove the dust from the paddy, if the paddy has dust when it is soaking it will pollute the water and influence the nutrition of rice.

- 2. Husking: After soaking and steaming it will be very easy to husk the paddy and save energy.

- 3. Milling: The pearling of pre-boiled rice cost much more time than normal paddy. The reason is that after soaking the rice is easy to become smectic. To avoid this problem we use blowing rice miller, and increase the rotating speed of rice miller,the rice bran transmission adopt neaumatic type to reduce the friction.

- 4. Polishing and Grading: Grading machine is used to separate different quality rice and separate broken rice from the good ones. Good rice come through the polishing machine, it will make the milling rice become more beautiful color and more smooth, thus to increase the quality of rice.

- 5. Color sorting: The rice we get from above step still has some bad rice, broken rice or some other grains or stone. So here we use color sorting machine to select the bad rice and other grains. Color sorting machine is an important machine to ensure we can get high quality rice.

- 6. Packing: The finish rice now is ready dear all! Let's use our automatic weighing and packing machine to make them into 5kg 10kg or 50kg bags. This machine is electric type, you can set it like a small computer, then it will start working according to your request.

Interested in this machine.

Application

Comparison before and after rice processing

-----processed rice is round and bright, and the food tastes better-----

Before rice processing