Rice Dryer

Paddy & Rice

-

Capacity

15T/B-50T/B

-

Product Name

low temperature circulating rice dryer

-

Structure

Circular

-

Drying method

indirect

-

Applicable material

Paddy & Rice

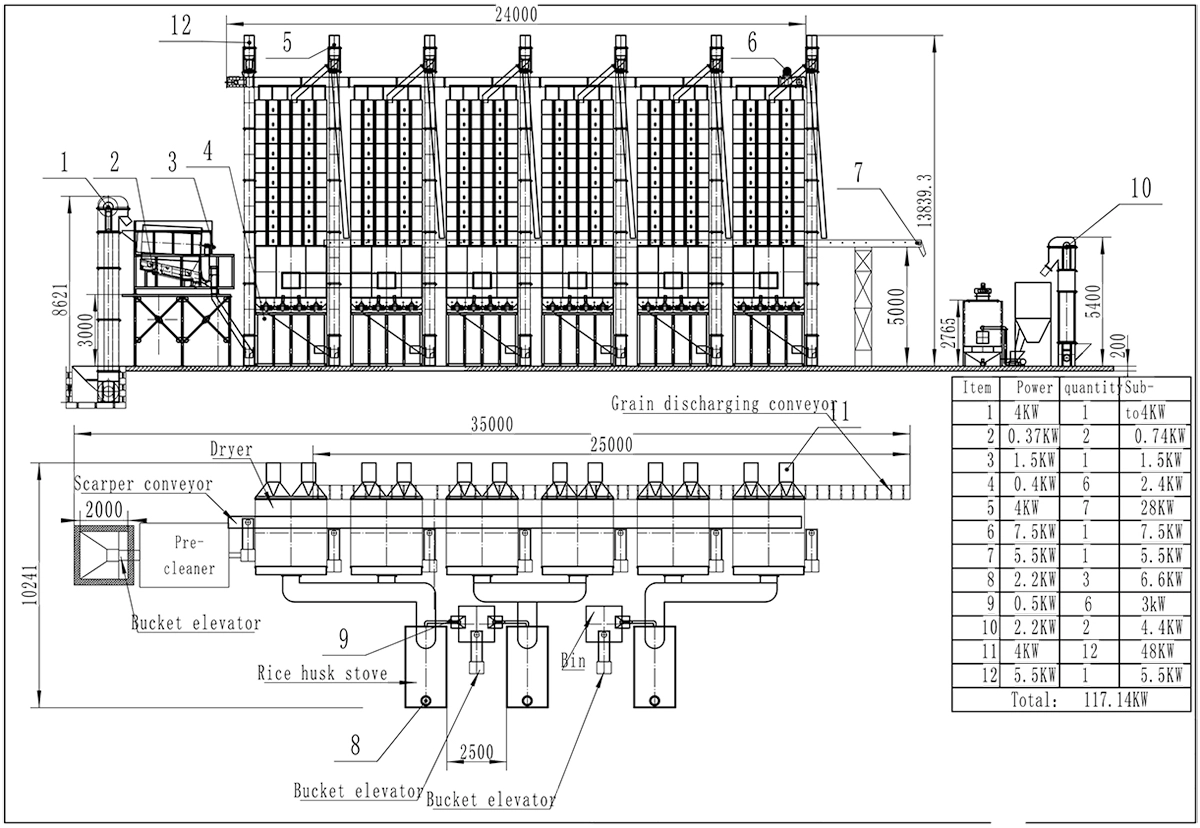

Product Introduce

The batch type low-temperature circulation rice dryer has a large capacity slow cooling layer, the height of the drying layer is 2652mm, the heat exchange area between hot air and rice is large, the drying is uniform and the drying rate is high. Adopt slow, low temperature and large air volume drying process to ensure low waist burst rate after drying.

The grain discharge device of grain dryer adopts slide valve structure, which has no damage to materials during operation, and the grain discharge speed can adopt frequency conversion speed regulation according to the output and water removal requirements.

Medium pressure, axial flow and multi blade ventilation fans are adopted, with low noise and low energy consumption. The whole dryer and the whole drying room are made into a closed structure, and equipped with a dust suction device, which avoids the dust flying in the working process of the dryer, improves the working environment, and can be used to promote the drying of grain and eliminate moisture.

Dryer

| Project | Company | Specifications | |||

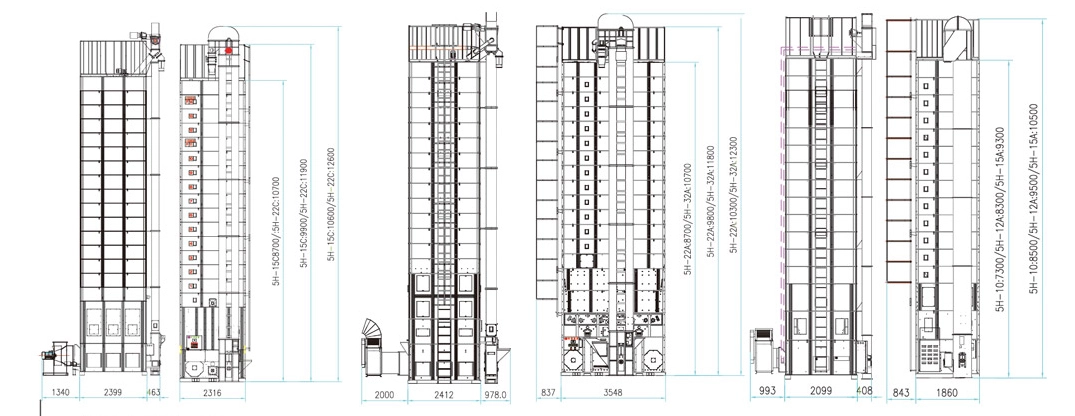

| Model specification | / | 5H-HC-10 | 5H-HC-15 | 5H-HC-20 | 5H-HC-35 |

| Structural style | / | Circulatory type | Circulatory type | Circulatory type | Circulatory type |

| Drying method | / | Indirect heating | Indirect heating | Indirect heating | Indirect heating |

| Dryer Body shape size(long*wide*high) | mm | 2700*3600*12000 | 2900*4050*10800 | 2900*4050*12200 | 3500*440013330 |

| Batch processing | t | 10 | 15 | 20 | 35 |

| Drying rate | %/h | 0.5-1.2 | 0.5-1.2 | 0.5-1.2 | 0.5-1.2 |

| Drying capacity | t*%/h | ≥3.88 | ≥7.8 | ≥7.8 | ≥13.6 |

| Installed capacity | m³ | 13.8 | 28 | 37 | 63 |

| Quantity of dry section/height | pcs/mm | 3/750 | 2/750 | 3/750 | 3/750 |

| Hot air temperature range | °C | 45-105 | 45-105 | 45-105 | 45-105 |

| Grain draining motor power | kw | 0.2 | 0.2 | 0.2 | 0.4 |

| Hoist productivit | t/h | 10 | 13.5 | 13.5 | 17.5 |

| Hoist motor power | kw | 2.2 | 2.2 | 2.2 | 2.2 |

Hot Blast Stove

| Model | 5H-40 | 5H-60 |

| Rated calorific(kcal/h) | <40 | <60 |

| Hot air output temp(°C) | ≤100 | ≤100 |

| Heating method | Hot air indirect drying, control temp automatically | |

| Ignition way | Manual ignition | Manual ignition |

| Feeding way | Manual/Automatic feeding(optional) | |

| Hot air output volume(/h) | 24000-36000 | 26000-48000 |

| Fuel | Rice husker,wood anthracite coal | |

| Heat efficient(%) | ≥85 | ≥85 |

| Weight(kg) | 4200 | 5100 |

| Dimension(L*W*H)mm | 2600*1500*2050 | 3250*1650*2250 |

| Power(kw) | 2.2 | 2.2 |

The performance values listed in the above table are reference values. The actual values will vary due to external air temperature, relative temperature / temperature, drying type, hot air temperature, moisture content before and after drying and other factors.

Structure

- 1. Hot blast stove: hundreds of manganese steel seamless steel pipes are used to form a set of heat exchange system. The flame, dust and waste gas produced by the furnace during combustion are isolated and heat exchanged through the inner cavity and outer wall of the pipe, and the exchanged clean hot air is sent to the dryer, so that the grain will not change color and taste.

- 2. Furnace: Q245 high-temperature boiler plate is used in the furnace. Refractory materials are added in the furnace to resist corrosion and high temperature and increase service life. Double layer steel plate with thermal insulation rock wool is used outside to reduce heat loss caused by external heat dissipation of the furnace.

- 3. Grain distribution system: the grain distribution system adopts multiple rounds of grain distribution, with uniform grain distribution, small resistance in the process of grain distribution, reduced bearing capacity of a single grain distribution wheel, reduced power required, low grain damage rate and long service life. The built-in dust removal system can effectively discharge the dust generated in the process of grain distribution in time.

- 4. New self flow discharge base: self flow discharge can reduce a screw conveyor and reduce the damage rate of grain when colliding with the conveying blade. 316 stainless steel bottom bin is adopted to reduce grain friction coefficient and improve the service life of dryer.

- 5. PLC automatic control system: two modes of one key start and manual operation, real-time computer monitoring of temperature and grain moisture, fault alarm and positioning display.

Features

- 1. Long service life: it can be used for more than 10 years. International technology and the latest technology are adopted. The main components are thickened plate, stainless steel flow channel (smooth material and smooth flow), galvanized plate, which is not easy to rust.

- 2. Low power: low heat consumption, energy conservation and environmental protection.

- 3.Fast precipitation and cost saving.

- 4. The dried grain is of good quality and does not change color and taste. Adopt low-temperature, constant temperature and full coverage drying, and fully cover and dry with clean heat source through thermal exchange, so as to ensure grain quality and no secondary pollution. Low waist burst rate ensures the rice yield of white rice processing section.

- 5.The performance is stable, the production capacity is about 30% higher than that of cross flow type, the precipitation rate is about 30%, and the damage rate is reduced by 1%.

- 6. The dried grains are evenly dried and the moisture content is consistent between the outside and inside, which makes the grains most likely to be preserved for a long time, and the mildew and moisture regain rate is more than 90% lower than that of high-temperature drying. There will be no burnt grain and burnt grain.

- 7.Large dustpan low-speed elevator to reduce rice crushing rate.

Pack and Ship

- 1. The spare parts and control cabinet will be loaded in wooden box.

- 2. The main machine is nude packing or plastic packing.

- 3. Also can do as customer's request.

Interested in this machine.

Application

The Rice Dryer are widely used in grain storage and processing enterprises.

paddy

barley

maize

sesame

black rice

soybeans

pea

red beans

coffee beans

orchid bean

lentils