Steel Silo

Fabricated steel silo is widely used in grain storage and processing industries such as grain depot, flour factory, starch factory, oil factory, feed factory, alcohol factory, distillery, seed company, port, farm and grain processing center. It can also store plastic particles, cement and other powdery materials, coal and so on.

-

Diameter

φ1.8-32m

-

Capacity

2.5-12000t

-

Type

2.5-1000t conical bottom steel silo and 1000-12000t flat bottom steel silo

-

Fabricated steel silo is widely used in grain storage and processing industries such as grain depot, flour factory, starch factory, oil factory, feed factory, alcohol factory, distillery, seed company, port, farm and grain processing center.

Product Introduce

Product Details

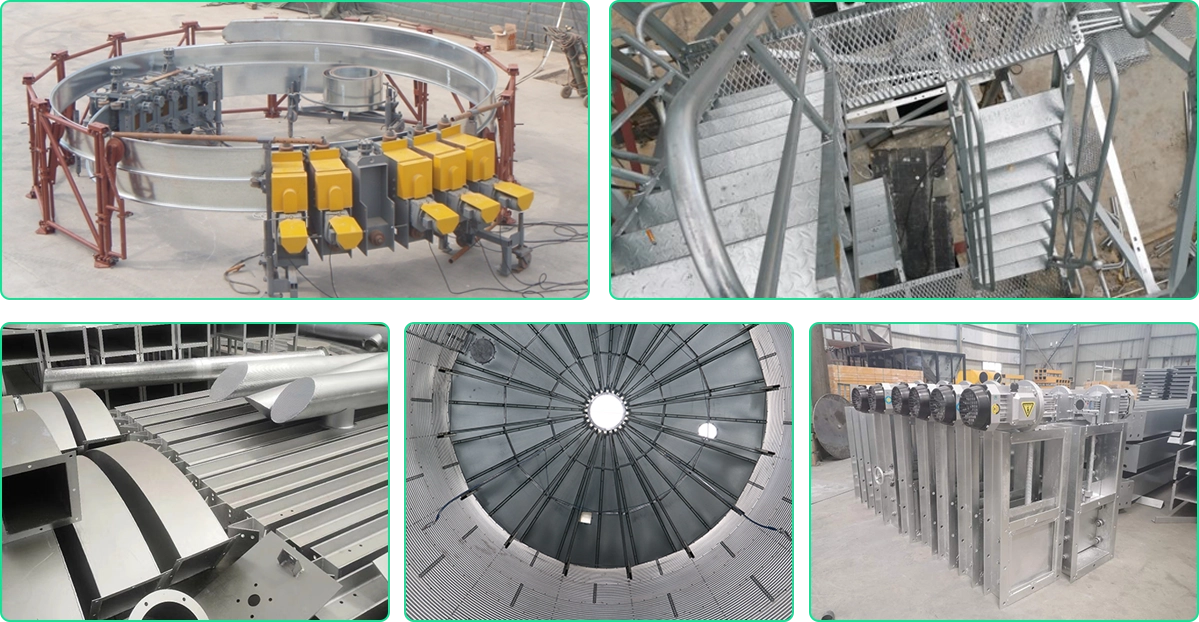

The fabricated steel silo, also called fabricated steel plate warehouse, assembly steel sheet silo, short as assembly silo. It is a steel sheet silo formed by punching the corrugated plate by mechanical rolling and molding, and connecting and assembling it with electric torque wrench through high-strength bolts. The wall plate of the assembly warehouse is corrugated. The plate is generally galvanized plate, which is usually 0.8 ~ 4.2mm thick, and the thickness of the warehouse wall can reach 8.4mm.

The moisture content of stored grain needs to be strictly controlled, usually no more than 13%. When stored for a long time, it is necessary to turn on the ventilation device regularly. Therefore, fabricated steel silo is equipped with domestic advanced spiral bite steel warehouse, wireless digital temperature measurement system, raw material cleaning and dust removal system, ventilation system and other storage system equipment.

| Flat bottom steel silo | Conical bottom steel silo | ||||||||||||

| Diameter (m) | Layers | Volume (m³) | Capacity (t) | Silo height (m) | warehouse full height (m) | Diameter (m) | Layers | Volume (m³) | Capacity (t) | Ring beam height (m) | Silo height (m) | warehouse full height (m) | |

| 4.584 | 3 | 63 | 47 | 3.43 | 4.78 | 3.667 | 1 | 22 | 18 | 2.77 | 1.19 | 5.05 | |

| 4 | 82 | 61 | 4.55 | 5.9 | 2 | 34 | 25 | 2.31 | 6.2 | ||||

| 5 | 100 | 75 | 5.67 | 7.02 | 3 | 46 | 34 | 3.43 | 7.32 | ||||

| 6 | 119 | 89 | 6.79 | 8.14 | 4 | 58 | 43 | 4.55 | 8.44 | ||||

| 6.417 | 5 | 203 | 152 | 5.67 | 7.55 | 5.5 | 4 | 142 | 106 | 3.73 | 4.55 | 9.89 | |

| 6 | 239 | 179 | 6.79 | 8.67 | 5 | 188 | 126 | 5.67 | 11.01 | ||||

| 7 | 257 | 206 | 7.91 | 9.79 | 6 | 195 | 146 | 6.79 | 13.25 | ||||

| 8 | 312 | 234 | 9.03 | 10.91 | 7 | 222 | 166 | 7.91 | 17.24 | ||||

| 8.250 | 7 | 465 | 349 | 7.91 | 10.32 | 9.167 | 8 | 752 | 564 | 5.5 | 9.03 | 17.24 | |

| 8 | 525 | 393 | 9.03 | 11.44 | 9 | 836 | 619 | 10.15 | 18.36 | ||||

| 9 | 585 | 438 | 10.15 | 12.58 | 10 | 900 | 675 | 11.27 | 20.60 | ||||

| 10 | 644 | 483 | 11.27 | 13.68 | 11 | 974 | 730 | 12.39 | 21.72 | ||||

| 10.084 | 8 | 789 | 599 | 9.03 | 11.97 | 11.834 | 9 | 1749 | 1312 | 7.35 | 10.15 | 21.27 | |

| 9 | 888 | 666 | 10.15 | 13.09 | 10 | 1894 | 1420 | 11.27 | 22.39 | ||||

| 10 | 977 | 733 | 11.27 | 14.21 | 11 | 2039 | 1520 | 12.39 | 23.51 | ||||

| 11 | 1067 | 800 | 12.39 | 15.33 | 12 | 2184 | 1638 | 13.51 | 24.63 | ||||

Advantages of fabricated steel silo

- 1. Light weight: 1 / 4-1 / 5 of the weight of concrete warehouse with the same capacity.

- 2. Large capacity range: it can make steel plate warehouse with single warehouse capacity from 5T to 16000T.

- 3. Firm structure and long service life: the spiral bite steel plate warehouse process is adopted to strengthen the cylinder strength, and all hot-dip galvanized raw materials are used to process the cylinder, well frame, trestle and other steel structures, which improves the product quality and has a service life of more than 30 years.

- 4. Simple operation and perfect equipment: simple operation, automatic feeding and discharging, perfect intelligent temperature measurement, humidity control and ventilation system, one key operation, saving time and trouble. It is convenient for mechanized operation and bulk grain storage.

- 5. Convenient installation, easy maintenance and money saving: short installation cycle, low maintenance cost and convenient disassembly.

- 6. Good air tightness: fire prevention, moisture-proof, heat insulation, ventilation, good air tightness, insect prevention, rat and bird prevention.

- 7. Small floor area and easy to manage: The spiral undercut steel plate silo is different from other steel plate silos, and the height and diameter can be arbitrarily selected in a large range. The minimum distance between the two warehouses is 500mm, which can make full use of the space and reduce the floor area. The spiral undercut steel plate warehouse has a high degree of automation, and is equipped with temperature measurement, material level and other equipment, which is very convenient for users to manage.

We can provide customers with the design, manufacturing, installation, commissioning, training and other services of steel plate warehouse projects of various specifications and models, mainly including the process design of complete sets of equipment, the design, manufacturing, installation and commissioning of steel plate warehouse and professional supporting equipment such as lifting, conveying, cleaning, drying, fluidization, temperature measurement, full measurement, fumigation, ventilation and automatic control system.

Auxiliary Equipment

Hydraulic unloading platform; Conveying equipment (hoist, belt conveyor, air cushion conveyor, scraper conveyor, screw conveyor and pneumatic conveying); Impurity removal equipment (double drum primary cleaning screen, air suction separator); Dust removal equipment (centrifugal dirt collector, pulse dust precipitator); Iron removal equipment; Ventilation equipment; Electronic control equipment; Temperature measuring system, drying equipment, robot stacking machine, robot unstacking machine, intelligent granary management system; Steel silo equipped with temperature measurement, ventilation, fumigation, material level.

Pack and Ship

- 1. The spare parts and control cabinet will be loaded in wooden box.

- 2. The main machine is nude packing or plastic packing.

- 3. Also can do as customer's request.

Interested in this machine.

Application

The Steel Silo are widely used in grain storage and processing enterprises.

paddy

barley

maize

sesame

black rice

soybeans

pea

red beans

coffee beans

orchid bean

lentils